Sponsored by Pickering Interfaces.

The following energy structure of alternative for EVs is 800 V, which requires parts to be suitably rated and extra sturdy than their 400 V counterparts. Nonetheless, most check tools used for 400 V EV system improvement may be re-used for 800 V if it might deal with the upper voltages, making the transition simpler for EV builders.

Obtain the white paper for additional data

The Advantages of {Hardware}-in-the-Loop and Simulation

In EV improvement, many corporations use {Hardware}-in-the-Loop (HIL) Simulation as a part of a test-driven technique. HIL simulation permits {hardware}, reminiscent of a Battery Administration System (BMS), to work together with a simulated setting that mimics real-world circumstances, together with bodily components like temperature and dynamic circumstances like movement and vibration. This helps engineers observe system conduct underneath practical situations.

Simulating these real-world circumstances permits early identification of design flaws and weaknesses, permitting for well timed enhancements and avoiding pricey points later in improvement. A key benefit of simulation in EV improvement is the flexibility to securely create excessive fault circumstances—reminiscent of speedy discharging and quick circuits—to judge BMS conduct with out risking harm to precise battery packs.

Making a HIL Check Platform

Whereas a HIL check platform could possibly be created from scratch, the price (each financial and time) of doing so tends to be prohibitive within the automotive {industry}. Subsequently, the usage of an industry-standard platform is very really helpful. Two requirements to think about are PXI and LXI, that are primarily based on the PCI and Ethernet {industry} requirements, respectively.

Each are supported by numerous world distributors with many industrial off-the-shelf merchandise accessible. Each present seamless vendor-independent plug-and-play. Of nice profit is that product longevity is assured, and the distributors have obsolescence administration processes in place.

400 to 800 V Testing Migration Path

Many OEMs and techniques homes within the automotive sector have invested in improvement and verification tools, together with HILS techniques, for EVs. The excellent news for these utilizing PXI or LXI platforms is that many present modules will nonetheless be usable when transitioning from a 400 V to an 800 V structure, permitting for vital reuse of the check system.

For parts that want substitute because of larger voltage rankings, PXI and LXI’s modularity and scalability make it straightforward to swap them out for upgraded variations.

Under, we talk about a couple of Pickering Interfaces merchandise appropriate to be used in 800V architectures.

Battery Cell Simulation

Cell-level simulation is important for EV improvement, because it permits the Battery Administration System (BMS) to acknowledge a completely charged pack precisely. This requires simulating particular person 3.2 to three.7 V cells and stacking them to attain the required voltage—96 cells for 400 V and 192 cells for 800 V.

The BMS additionally manages cell balancing, necessitating the flexibility to simulate every cell’s cost stage throughout relaxation, charging, discharging, and introducing imbalances.

By simulating cells independently, present tools may be tailored for 400 V and 800 V architectures by including extra modules (simulated cells) so long as the emulator can deal with larger voltages.

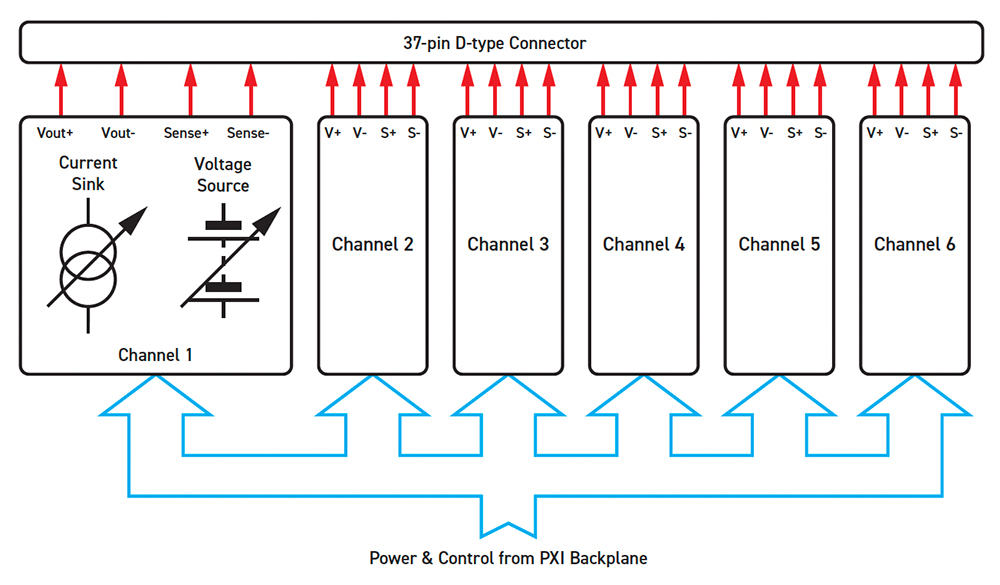

Determine 2 exhibits the block diagram of a multi-channel battery simulator module accessible in PXI (41-752A) and PXIe (43-752A). It contains a number of energy provide channels (two, 4 or six per slot) able to supplying as much as 7V and 300mA, that are remoted from each other and from system floor. Subsequently, the module’s energy provides can be utilized to emulate a stack of battery cells. Additionally, every channel can sink as much as 300mA to emulate a battery underneath cost. Every channel supplies impartial energy and sense connections, permitting the simulator to sense a distant load and proper for wiring losses.

Excessive Voltage Switching

Excessive voltage switching is utilized in check techniques for connecting or disconnecting indicators and routing them between factors, achieved via three configurations:

- Uncommitted switches (e.g., single-pole, single-throw, usually open or closed).

- Matrices that join any enter to any output.

- Multiplexers (MUXs) that join a single enter to a number of outputs.

These configurations are available in numerous relay and connection counts, with modules able to switching a number of kV, making them appropriate for purposes like isolation switching and breaker simulation.

Excessive-voltage switching may be achieved utilizing a number of options from Pickering Interfaces: over 60 PXI/PXIe modules and 28 LXI modules. For instance, the 40-323-901 (PXI) and 42-323-901 (PXIe) are 14xSPST relay modules appropriate for high-voltage energy switching purposes. They will deal with present as much as 0.25 A for chilly switching as much as 9 kVDC (9 kVAC peak) and for warm switching as much as 7.5 kVDC (7.5 kVAC peak).

RTD Simulation

Temperature have to be monitored at numerous areas in an EV, together with the battery pack, motors, energy inverter, charger port, and cabin. A preferred and cost-effective possibility is the resistance temperature detector (RTD), with the PT100 being a standard kind with a resistance of 100Ω at 0°C. RTDs can have both a optimistic or adverse temperature coefficient (PTC or NTC).

Simulating RTDs is useful since testing the design underneath a variety of temperatures would in any other case require costly environmental check chambers.

PXI-based RTD simulator modules can be found from a number of corporations. For instance, Pickering Interfaces has many appropriate modules for RTD simulation, together with the 40-263 (with 4, 8, 12, 16, 20 and 24 channels) that may simulate the resistance vary 40 to 900Ω, which equates to a temperature vary of -150 to 850oC, to a decision of lower than 10mΩ. Determine 3 exhibits an instance module.

To a lesser diploma, thermocouples are additionally utilized in EVs, primarily in product improvement, because of their excessive accuracy. Their outputs, that are small voltages (a couple of millivolts), may be simulated. Pickering Interfaces provides PXI millivolt thermocouple simulator modules with 8, 16, 24, or 32 channels, offering extremely correct low-voltage sources. Every channel can function throughout three voltage ranges to simulate any normal thermocouple kind used within the {industry}.

Fault Insertion/Injection

The flexibility to insert faults throughout system improvement and verification is important. As talked about above, techniques would possibly have to instigate a protected shutdown or, if redundancy is in-built, energy re-routed if a fault is detected. This performance must be absolutely validated.

Pickering Interfaces’ vary of PXI fault insertion items is explicitly designed for safety-critical purposes the place the conduct of a management system, reminiscent of a BMS, must be completely evaluated underneath all potential real-world fault circumstances.

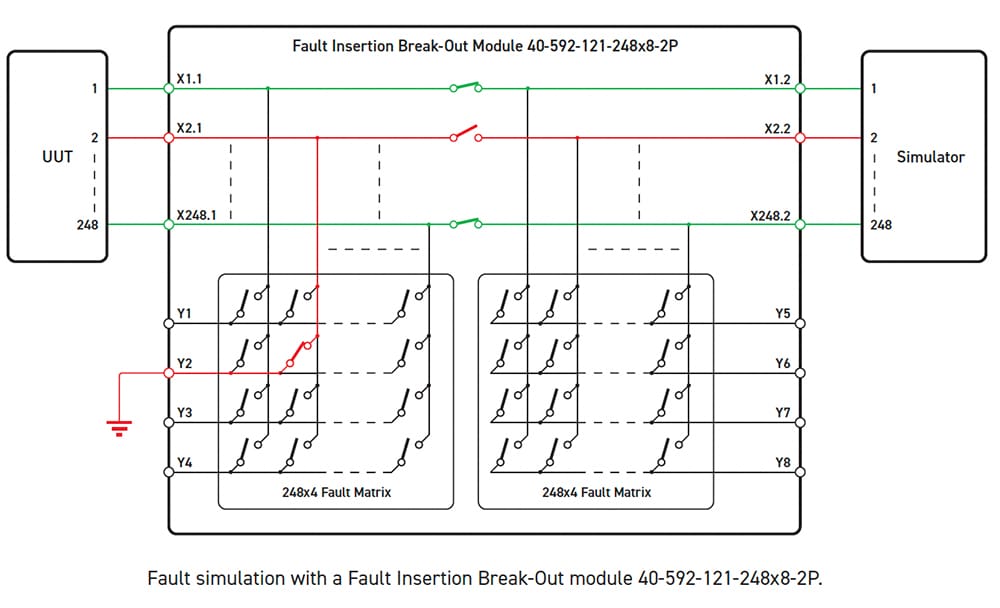

For instance, the 40-592 fault insertion break-out (FIBO) is a large-scale, high-density switching matrix. It’s certainly one of a variety of modules designed for purposes requiring the simulation of quite a lot of faults in advanced designs with a excessive variety of indicators/connections, reminiscent of a battery pack.

Open circuits and quick circuits (to a different sign/element or to the bottom) are typical faults that may be simulated.

Abstract

Shifting from 400 to 800 V architectures provides advantages like larger efficiency and sooner charging. Nonetheless, it requires higher sturdiness and security. Simulation is the most secure technique to confirm an EV’s structure and techniques, permitting for straightforward check circumstances and outcomes traceability. Utilizing PXI and LXI-based check tools supplies producers with a straightforward migration path. This allows optimizing key system parts and accelerates system improvement via automated testing.