Ditch the plug! Make wi-fi EV charging a actuality now!

Distinctive elements guarantee security, effectivity and reliability.

Think about an EV charging expertise that’s as seamless and intuitive as parking your automobile—simply “park, cost, and go.” For the end-user, the attraction is obvious:

- No extra heavy cables

- No fumbling with connectors

- No publicity to probably soiled or broken charging tools

EV homeowners envision pulling into their storage, a chosen parking spot, or a public charging station and effortlessly charging their car with out ever leaving the motive force’s seat. This comfort makes each day charging extra user-friendly and enhances security by eradicating bodily connectors altogether.

Understanding this user-centric imaginative and prescient is essential for wi-fi EV charging system designers. By delivering environment friendly, dependable, and quick wi-fi charging, designers can unlock a game-changing profit that mixes ease, consolation, and peace of thoughts for EV drivers.

Whereas present wi-fi EV chargers can provide as much as 20 kW to cost batteries in 4 to 6 hours, future wi-fi chargers will ship 100 kW and be capable to enhance battery cost state by 50 % in below 20 minutes.1

Wi-fi charging stations have to be quick, protected, environment friendly, and dependable to speed up adoption.

This text explores the technical concerns and progressive approaches required to realize this expertise, guaranteeing wi-fi charging options meet efficiency and consumer expectations within the ever-evolving EV panorama. It presents 4 elements that handle the important must create designs that guarantee charger circuit safety, security monitoring, and quick, environment friendly energy supply.

Wi-fi charger description

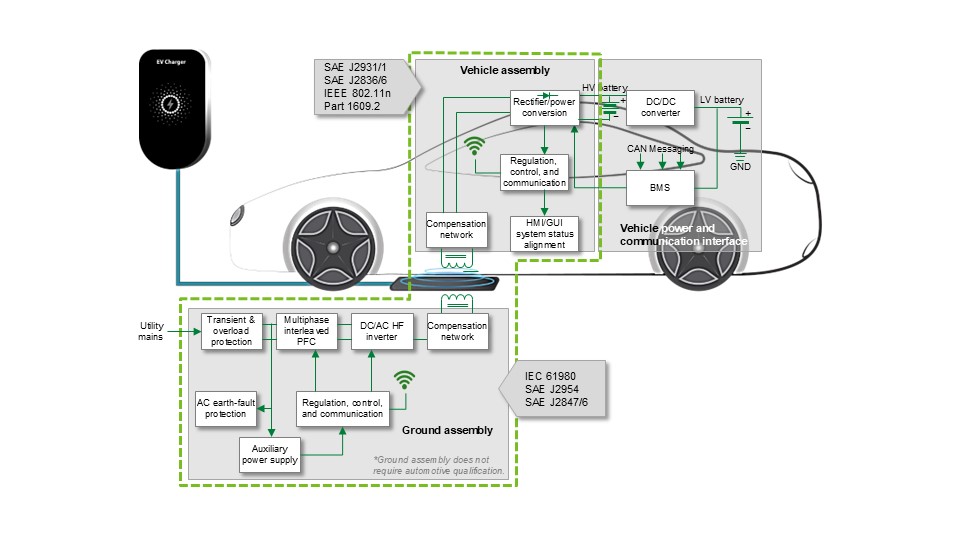

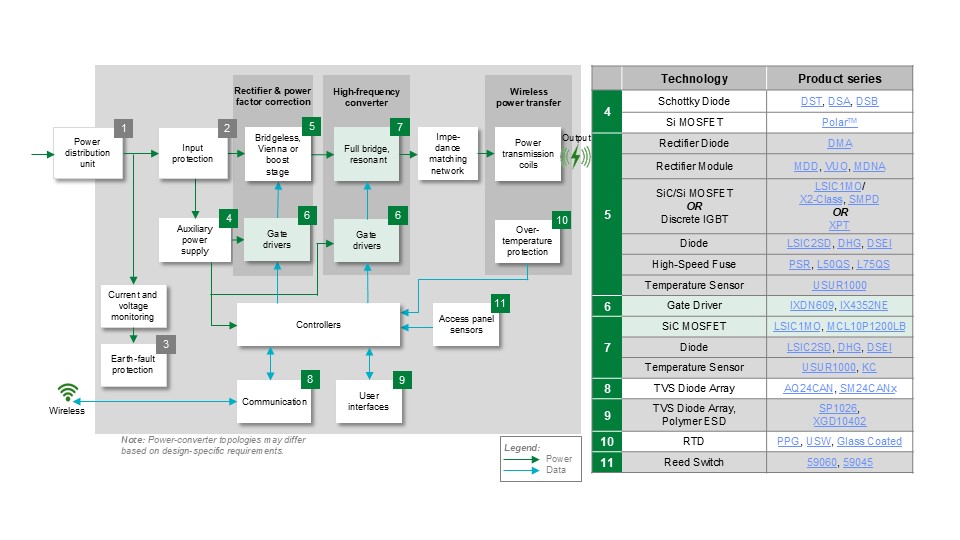

A wi-fi charger is an AC-AC converter that converts 50/60 Hz energy to energy within the frequency vary of 130 kHz. Resonant frequency relies on topologies and Energy semi conductor know-how (Si/SiC/GaN). Energy supply could be as much as 20 kW. Determine 1 illustrates a wi-fi charger and its load, the EV. The key energy and management circuit blocks within the charger and the car are additionally outlined.

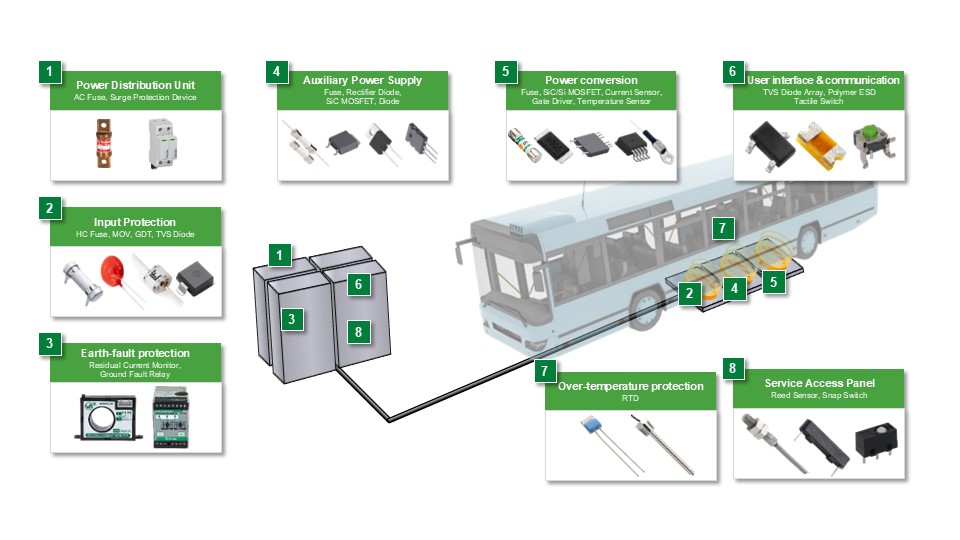

Security and reliability concerns embody overcurrent safety, overvoltage safety, overtemperature, and floor present monitoring. Optimizing effectivity requires designing with low energy loss elements. Determine 2 illustrates elements that present circuit safety and excessive effectivity for the circuits of a typical wi-fi charger design. The sensors provide temperature monitoring and enclosure entry safety.

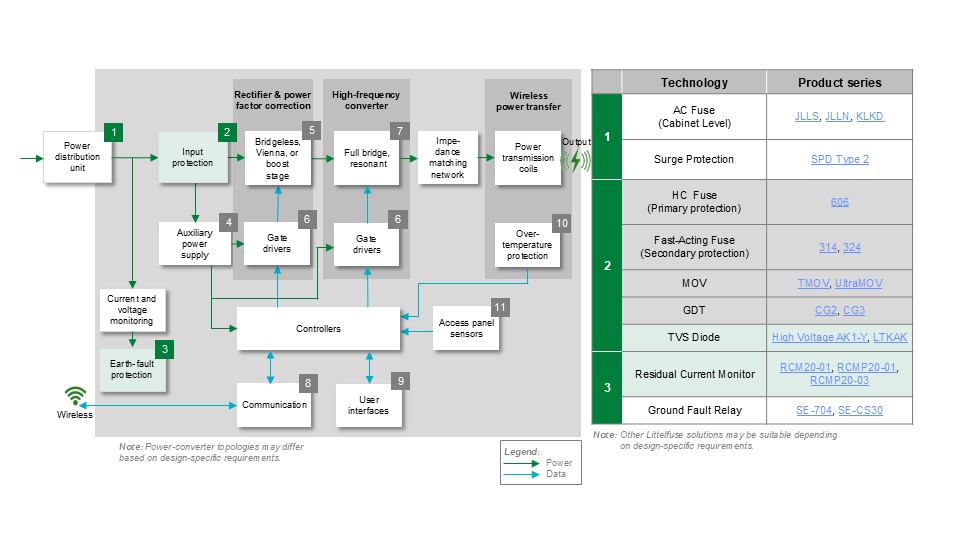

Figures 3 and 4 present an instance wi-fi charger in a extra detailed block diagram. The adjoining desk in Determine 3 lists the elements that equip the charger with safety from electrical hazards. Determine 4 primarily reveals the elements that produce effectivity and important sensing.

Circuit safety and security elements

The Enter Safety circuit homes the primary overcurrent and overtemperature safety elements. Advisable elements embody a excessive present fuse for the ability supply circuitry and a fast-acting fuse to guard the low energy Auxiliary Energy Provide and the management circuitry. A steel oxide varistor (MOV) in sequence with a gasoline discharge tube absorbs overvoltage transients. Overvoltage transients outcome from lightning which might induce a voltage surge on the AC enter strains. As well as, electrical masses switching on and off can induce AC line voltage surges.

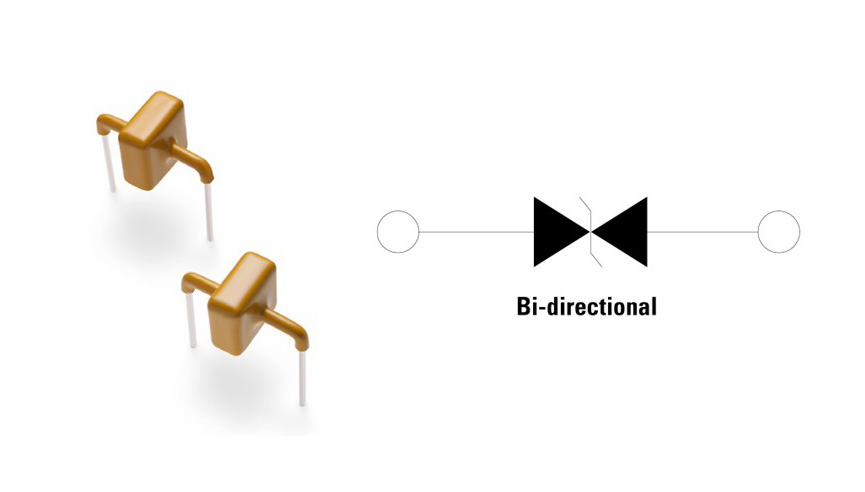

A particular part that may seize parts of a voltage transient that has handed by means of the MOV and gasoline discharge tube is a transient voltage suppressor (TVS) diode. TVS diodes have decrease clamping voltages, and so they function a lot quicker than MOV units. The particular diodes can guarantee safety of downstream circuitry. They will soak up a one kA pulse and reply to a transient in below one nanosecond. TVS diodes can present safety from electrostatic discharge (ESD) through-the-air strikes of as much as 15 kV and from direct contact discharges as much as 8 kV. Bi-directional fashions and fashions which are lower than one tenth the dimensions of conventional discrete options can be found. TVS diodes can have axial lead or floor mount type elements. Determine 5 reveals a TVS diode and its purposeful diagram, utilizing the AK1-Y Sequence TVS Diode from Littelfuse for instance. This part will dispense the mandatory safety from each ESD and different transients to keep away from injury to semiconductor circuitry within the wi-fi charger.

With techniques corresponding to wi-fi EV chargers, monitoring floor currents is important for the safety of personnel. The Earth-Fault Safety circuit performs the bottom present monitoring operate. Littelfuse provides new residual present screens for this circuit that detect each AC and DC floor fault currents. The brand new sequence, the RCMP20 Residual Present Monitor Sequence for Mode 2 and Mode 3 wi-fi charging stations, provides the most important present transformer aperture to help greater AC charging currents. The residual present screens have delicate, typical journey thresholds of 4.5 mA DC and 22 mA AC. Moreover, the screens make the most of built-in conductors with greater cross-sectional areas to offer higher thermal administration and scale back the rise within the printed circuit board (PCB) temperature. The result’s a extra compact and dependable design that doesn’t compromise efficiency. As well as, the screens have excessive immunity to electromagnetic interference (EMI), which improves charger circuit reliability and minimizes false circuit journeys. The screens could be mounted both horizontally or vertically to permit designers flexibility to optimize area utilization. Determine 6 shows the fashions within the Residual Present Monitor sequence. (View the video.)

Elements for maximizing effectivity and reliability

Programs, corresponding to wi-fi charging techniques, eat a considerable quantity of energy. Optimizing a design for effectivity reduces energy consumption and utility prices and reduces warmth buildup. Diminished generated warmth lowers the interior temperature rise within the system and enhances system reliability. The usage of two elements within the energy supply circuitry can contribute to greater effectivity and better reliability. The 2 elements are gate drivers and SiC MOSFETs.

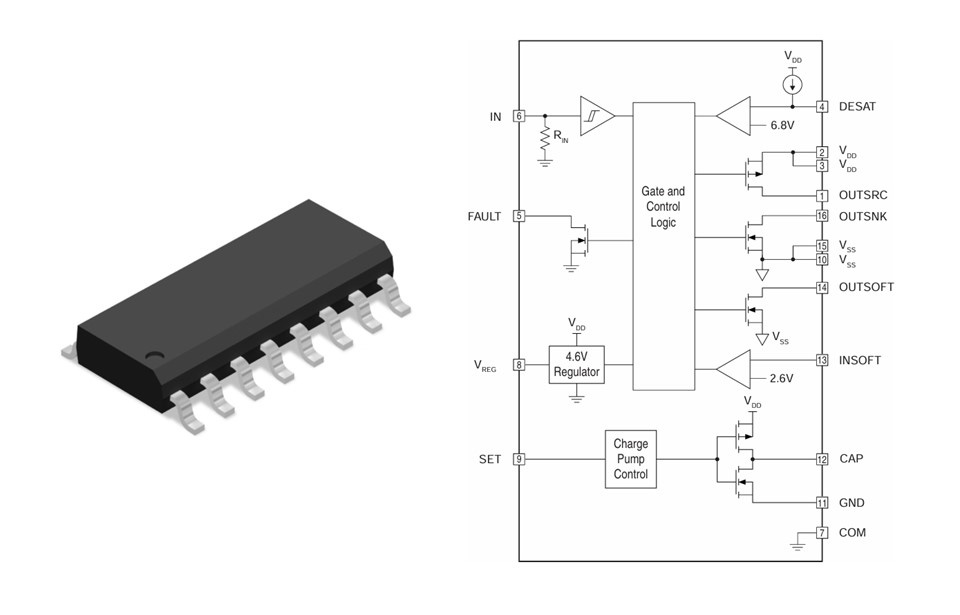

Gate drivers management the Energy SiC MOSFETs and the IGBTs within the Bridgeless, Vienna, or Increase Rectifier and the Full Bridge, Resonant Excessive-Frequency Converter circuits. The drivers have separate 9 A supply and sink outputs, which allow programmable turn-on and turn-off timing whereas minimizing switching losses. An inside unfavorable cost regulator offers a selectable unfavorable gate drive bias for improved dV/dt immunity and quicker turn-off. The gate drivers reduce switching occasions with turn-on and turn-off propagation delay occasions of sometimes 70 and 65 nanoseconds. The standard worth for rise time and fall time outputs is ten nanoseconds.

To make sure strong operation, the gate drivers have desaturation detection circuitry which senses a SiC MOSFET overcurrent situation and initiates a smooth flip off. This circuit prevents a probably damaging dV/dt occasion. Extra safety options embody UVLO detection and thermal shutdown. Determine 7 illustrates theLittelfuse IX4352NE SiC MOSFET and IGBT Driver IC, a high-speed gate driver with options that present dependable management of a SiC MOSFET.

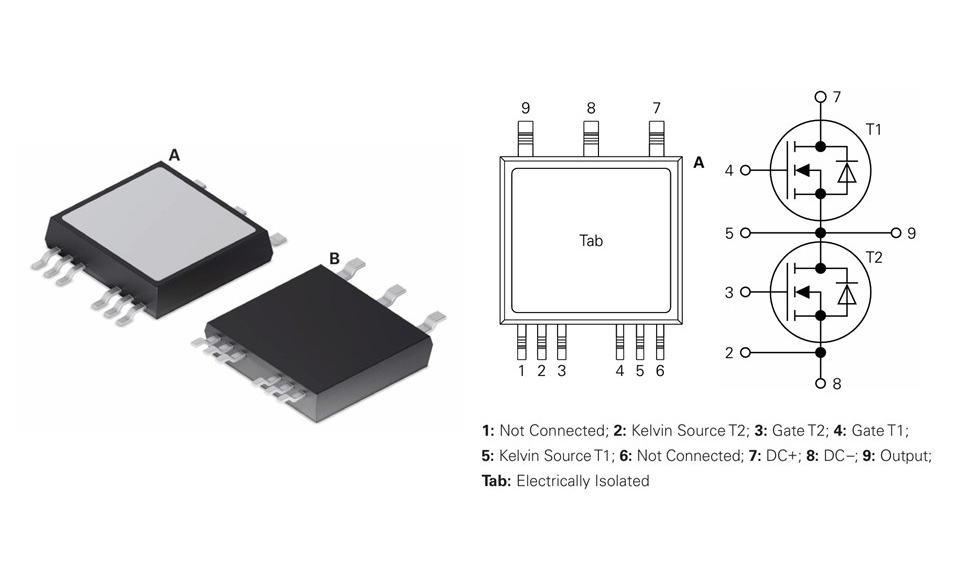

Excessive-power SiC MOSFETs drive the ability transmission coils. Half-bridge packages have a Drain-Supply voltage of 1200 V and a drain present of as much as 19.5 A. Together with delivering excessive energy, the MOSFETs reduce on-state energy consumption with a typical RDS(ON) of a low 160 mΩ. SiC MOSFETs have low switching energy losses as a result of a typical low gate cost, brief turn-on, and turn-off delay occasions, and present rise and fall occasions.

A DCB-based remoted package deal improves thermal resistance and energy dealing with functionality. A complicated topside cooled package deal simplifies thermal administration. The Littelfuse half-bridge SiC MOSFET MCL10P1200LB Sequence, proven in Determine 8, yields excessive effectivity with superior packaging to scale back part rely and to optimize for top reliability.

Collaborate with consultants for a dependable wi-fi charging resolution

Safety towards electrical hazards corresponding to overcurrent, overvoltage, ESD, and overtemperature is essential for guaranteeing dependable operation. The 4 beneficial elements described within the previous paragraphs allow designers to develop strong, protected, and dependable wi-fi EV charging stations.

To develop a strong and environment friendly product, designers ought to contemplate using the part producers’ utility engineers to avoid wasting design time and compliance prices. The applying engineers can assist with the next:

- Collection of cost-effective safety, sensing, and high-efficiency elements

- Information of the relevant security requirements

- Littelfuse can carry out pre-compliance testing to keep away from compliance check failures and save on mission delays and added prices for a number of compliance check cycles.

Collaborating with the part producer’s utility engineers and utilizing the beneficial elements will assist to provide strong, dependable, and environment friendly wi-fi EV charging options.

To be taught extra about circuit safety, sensing, and energy administration options for wi-fi EV charging design, obtain the information, Supercharged Options for EV Charging Stations, courtesy of Littelfuse, Inc.

Contact Littelfuse for extra data on making your wi-fi charging system design protected, environment friendly and dependable.

References:

1L. Blain. World’s quickest wi-fi EV charger unlocks 100 kW parking spots. New Atlas. March 18, 2024.