To help using hydrogen as a climate-friendly vitality service, Hengst has developed a modular system of varied filtration options for business automobiles and off-highway functions. This consists of ion exchangers and cathode air filters for gas cells, in addition to disc separators and energetic crankcase air flow for hydrogen combustion engines, which make sure the service life, effectivity, efficiency and security of the drive even below harsh working situations.

The coolant of a gas cell is enriched with ions throughout operation. These are brought on by getting older merchandise of the coolant itself or by parts within the cooling circuit. Efficient filtration is subsequently required for the protected operation of the gas cell. The Blue.iox ion exchanger from Hengst gives notably excessive safety with minimal upkeep. The distinctive design of the filter cartridge with axial filter circulate and the particular blended mattress resin system for cation and anion change guarantee excessive filtration efficiency over all the service interval.

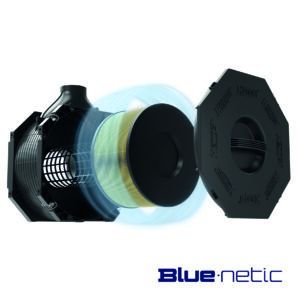

Particular necessities are additionally positioned on filtration within the air circuit of a gas cell. The consumption air should be very successfully cleaned of particles from the skin air to make sure lengthy service life and excessive efficiency. As well as, pollution corresponding to nitrogen oxides (NOx), ammonia (NH3) and sulfur oxides (SO2) can result in undesirable deposits within the gas cell and harm it. A specifically developed cathode air filter system Blue.netic from Hengst with a multilayer construction reliably protects the gas cell parts from particles and dangerous gases.

The necessities for filter methods for hydrogen engines are corresponding to these for typical gasoline or diesel engines. Nevertheless, the elevated introduction of water into the engine oil and the simple flammability of hydrogen should be thought of as further challenges. Blowby gases that enter the crankcase by way of the cylinders kind an explosive combination at concentrations above 3.5% by quantity, which ignites on scorching engine parts. The energetic air flow system developed by Hengst minimises the hydrogen focus within the crankcase and counteracts the chance of ignition.

The vast world of filtration

As a household operated firm with 3,600 workers at 25 areas, Hengst Filtration is thought worldwide for its progressive filtration and fluid administration options.

Our merchandise are utilized in hundreds of thousands of functions around the globe to make one thing cleaner. However we are able to do even higher. We predict filtration – in every little thing we do. We ship forefront filtration methods for the fields of plant and machine engineering, industrial filtration, hydraulics, life science and well being care. Our custom-tailored options are utilized in medical cleanrooms, air-con methods, cleansing machines, industrial methods, electrical instruments and robots.

We’re additionally an OEM provider for the worldwide automotive and motor business and a improvement companion for sustainable drivetrain and mobility ideas.

Making our planet a purer place

Mobility, well being, financial system, environmental safety and sustainability: our every day work focuses on the main problems with our time. With the purpose of creating the planet a cleaner place. This allows worldwide forward-looking applied sciences in all industries.

EIMA Worldwide attendees can go to Hengst at Corridor 15 / Sales space A10.